Horticultural crop cultivation faces constant new challenges: climate change, plant diseases, and resource scarcity demand innovative solutions from growers. One promising technology for improving yields is the use of nanobubbles in irrigation water.

Nanobubbles typically refer to bubbles smaller than 200 nm—gas-filled cavities in water that usually contain air or oxygen. Normal water bubbles rise quickly to the surface and burst, whereas hydrophobic nanobubbles maintain their shape much longer, storing oxygen in the water and increasing its overall oxygen concentration.

There are only a few companies in Europe that add oxygen to water. Finland also has a technology developer, EOD Europe, which has worked extensively with research institutes and growers to find solutions to cultivation challenges.

“Nanobubbles not only increase the oxygen content of water but also improve the aeration of the growing medium, as they remain in the substrate,” explains Henna Niskakoski, Scientific Director at EOD Europe.

“In addition, our trials have shown that nanobubbles reduce biofilm formation in pipelines—the accumulation of organic matter. When biofilm decreases, fertilizers become more effective,” she continues. Drip or trickle emitters stay cleaner, reducing the need for maintenance.

Plant Resilience Improves with Fertigation

Adding oxygen to irrigation water—fertigation—has been studied relatively little. EOD’s research has found that plants use nutrients more efficiently, and fertilizer amounts can be reduced by 10–20%. Because nanobubbles lower water’s surface tension, water becomes more accessible to plants. These results align with international studies.

“Oxygen improves nutrient uptake and increases stress tolerance. We’ve also seen that root microbes multiply and overall plant health improves, which boosts both yield quantity and quality,” Henna adds.

Measuring Oxygen Levels in Water Pays Off

Professional growers monitor many factors, but rarely the oxygen level of irrigation water. Although Finnish water quality is often excellent, blind trust is not advisable.

Many farms draw irrigation water from sources where oxygen levels are already low.

“Moreover, oxygen levels always drop as temperature rises, and the smaller the water source, the faster it warms,” Henna notes.

Typically, irrigation water has a dissolved oxygen (DO) level of about 5–8 mg/L. If all other growing conditions are optimal, an unrestricted oxygen level would ideally be 11–20 mg/L. As water temperature rises, oxygen solubility decreases rapidly, and pathogens thrive better in warm water.

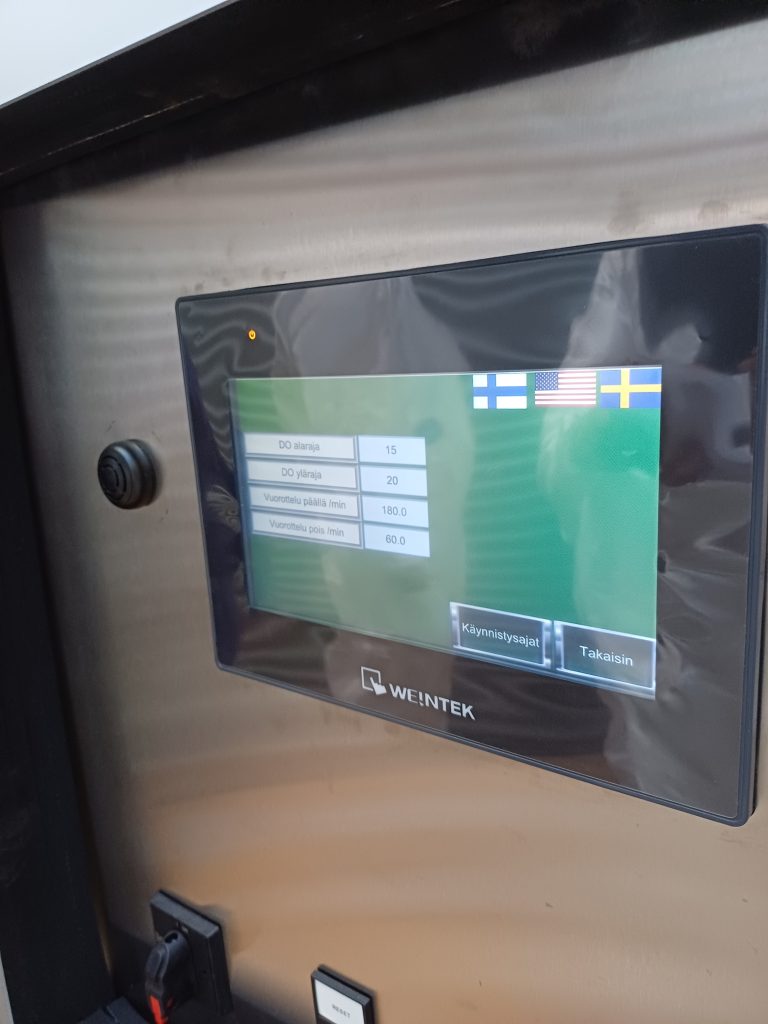

Several methods exist for producing nanobubbles in water. EOD’s oxygenation technology is based on a hydrodynamic process that mimics natural oxygen transfer. In this method, oxygen gas separated from air is mixed with water, and a pressure change creates nanobubbles.

“We chose this method because it’s easy to maintain and tolerates slightly larger particles. Our goal was to provide growers with a long-lasting fertigation system that meets farm needs and operates fully automatically,” Henna explains. The EOD system is developed, designed, and manufactured in Finland, and its remote monitoring ensures fast support.

Is Investing in Nanobubbles Worth It?

Erno Mikkola, owner of Kitsbölen Kotitila in Sauvo, has used oxygen enrichment in irrigation water for nearly four years. During this time, yields have increased annually, and common strawberry diseases have remained under control. The farm draws irrigation water from a nearby pond, where oxygen levels are very low during warm weather—sometimes as low as 4 mg/L.

“Our irrigation water quality isn’t ideal. In 2022, when EOD contacted us, we joined a project testing the effects of oxygen enrichment. The first results were promising, so we decided to continue trials on our farm,” Erno recalls.

Initially, oxygen enrichment was applied to a small test area. When yields improved, the treated area was expanded, and now all tunnel zones receive oxygen-enriched water.

“System implementation was easy, and now we monitor oxygen levels routinely. They stay between 14–20 mg/L on average,” Erno says.

According to EOD, average yield increases in berry farms and greenhouses have been about 5–15%. Growers know that many factors influence yield.

“Fertigation isn’t a miracle cure. But when other growth factors are in place, fertigation can boost productivity on the same area. It’s actually a very ecological solution,” Erno reflects. The farm has also observed a significant reduction in diseases such as powdery mildew.

“Overall, we’re very satisfied with the investment,” Erno concludes.

Text and images: Eija Lankinen and EOD archives

The original article was published in the 2026 Horticultural Calendar.

Interested?

Please contact us for further information.